The Precision Craft of Diecasting: Revolutionizing Manufacturing

The Precision Craft of Diecasting: Revolutionizing Manufacturing

Blog Article

Diecasting is a highly-specialized production process that transforms the molten metal into precisely defined parts using high-pressure molds. The technique is now indispensable for a wide range of industries such as electronics, aerospace, automobiles and other consumer goods because of its capability to make complex shapes with remarkable accuracy and consistency. In combining the principles of metallic engineering with cutting-edge technology it provides unparalleled precision and efficiency, making it the foundation of modern manufacturing. This article delves into intricate world of diecasting, exploring its process, advantages as well as the wide range of applications.

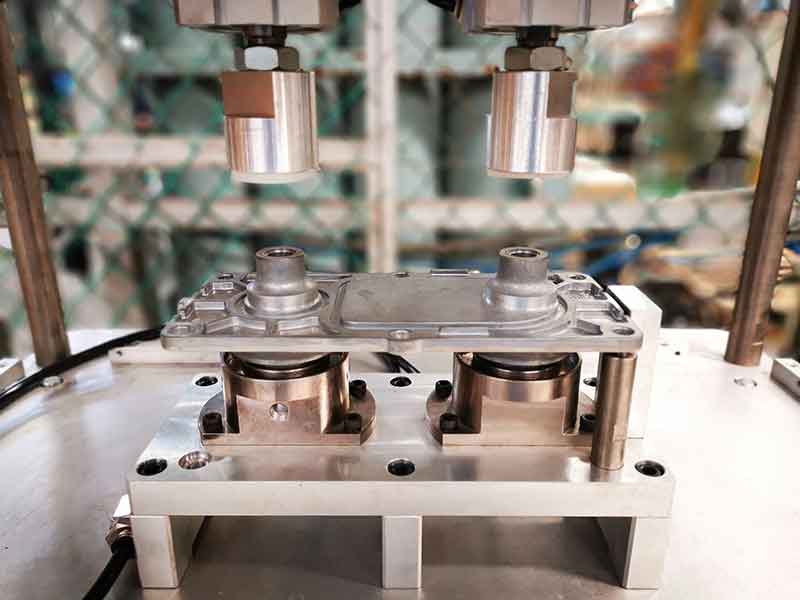

Diecasting is the usage of molds, known as dies, which are crafted out of high-quality stainless steel, which can stand the tough conditions encountered in the casting process. The dies are designed using precision and often incorporate intricate details and fine tolerances to guarantee precision of the final product. The process of diecasting involves molten metal-commonly aluminum, zinc or magnesium is in the dies under very high pressure. Rapid injection and rapid hardening results in products with excellent dimensional stability and a polished surface, which reduces the requirement for additional machining or finishing. Precision of the dies allows the manufacturing of complex geometries that might be impossible or difficult to achieve with other manufacturing processes.

One of the most significant benefits of diecasting is its capacity to manufacture parts with high precision in dimensional measurement and smooth surface finish. The high-pressure injection ensures that the molten metal conforms precisely in the mold resulting with parts that need only minimal processing or finishing. This kind of precision is ideal for producing complex geometries and thin-walled pieces that would be challenging or impossible to achieve through other manufacturing techniques. In addition, diecasting produces components with precise tolerances and exceptional repeatability. This makes it perfect for large-scale production. The effectiveness of this process is also a source of cost savings because the higher production rates lower labor costs and waste material.

Diecasting's versatility is apparent in its extensive use across various industries. For instance, in the automobile industry For instance, diecast parts are fundamental when it comes to the manufacture of engine components such as transmission housings, transmission components, and other structural components. The components are benefited by the durability and strength offered by diecasting, as well being able to create components that are lightweight, which can improve fuel efficiency. in the aerospace field, the need for high-strength parts that are lightweight is crucial Diecasting can provide the high-quality and durability needed for these demanding tasks. Electronics for consumer use also depend heavily upon diecasting for the production of robust and accurate housings as well as internal components to ensure the reliability and longevity of devices. Medical, telecommunications and power tools sectors further illustrate the broad applicability and importance of diecasting in modern manufacturing. To obtain further details please visit site

Diecasting's versatility extends into a variety of applications in various sectors. For instance, in the automobile industry Diecast components play an integral role in the creation of engines, transmissions and structural parts, contributing in the creation of smaller, lighter vehicles that are more efficient in fuel consumption. Within the electronics industry it is utilized for the production of heat sinks, connectors and housings, to ensure optimal thermal management as well as longevity for electronic devices. The consumer goods industry also has a lot to gain from diecasting, with applications that range from kitchen appliances to power tools and toys. Diecasting's versatility to different metals as well its ability to manufacture parts with intricate patterns make it ideal for a variety of types of applications. Each profiting from the distinctive benefits that diecasting provides.

Diecasting is an incredibly effective and adaptable manufacturing process which is essential to the production of intricate metal components with high precision and consistency. Its capability to make components with fine details with tight tolerances and flawless surface finish makes it an indispensable tool for all industries ranging from automotive and aerospace to consumer electronics and beyond. Its use of various material types further increases the flexibility of diecasting. This allows manufacturers to pick the right alloy to meet their needs. Technology advances, and demand for high-quality, cost-effective components continues to grow and increase, diecasting will continue to be crucial for manufacturing which will drive innovation and superiority in production.